Manufacturing

Production Lines

Automated insulated glass (IG) manufacturing revolutionizes the production process, increasing efficiency and quality. Advanced machinery precisely applies spacer systems, and seals units with accuracy. Automated processes reduce human error, enhance productivity, and ensure consistent results. This technology streamlines IG manufacturing, allowing for faster turnaround times and delivering superior, reliable products to meet customer demands.

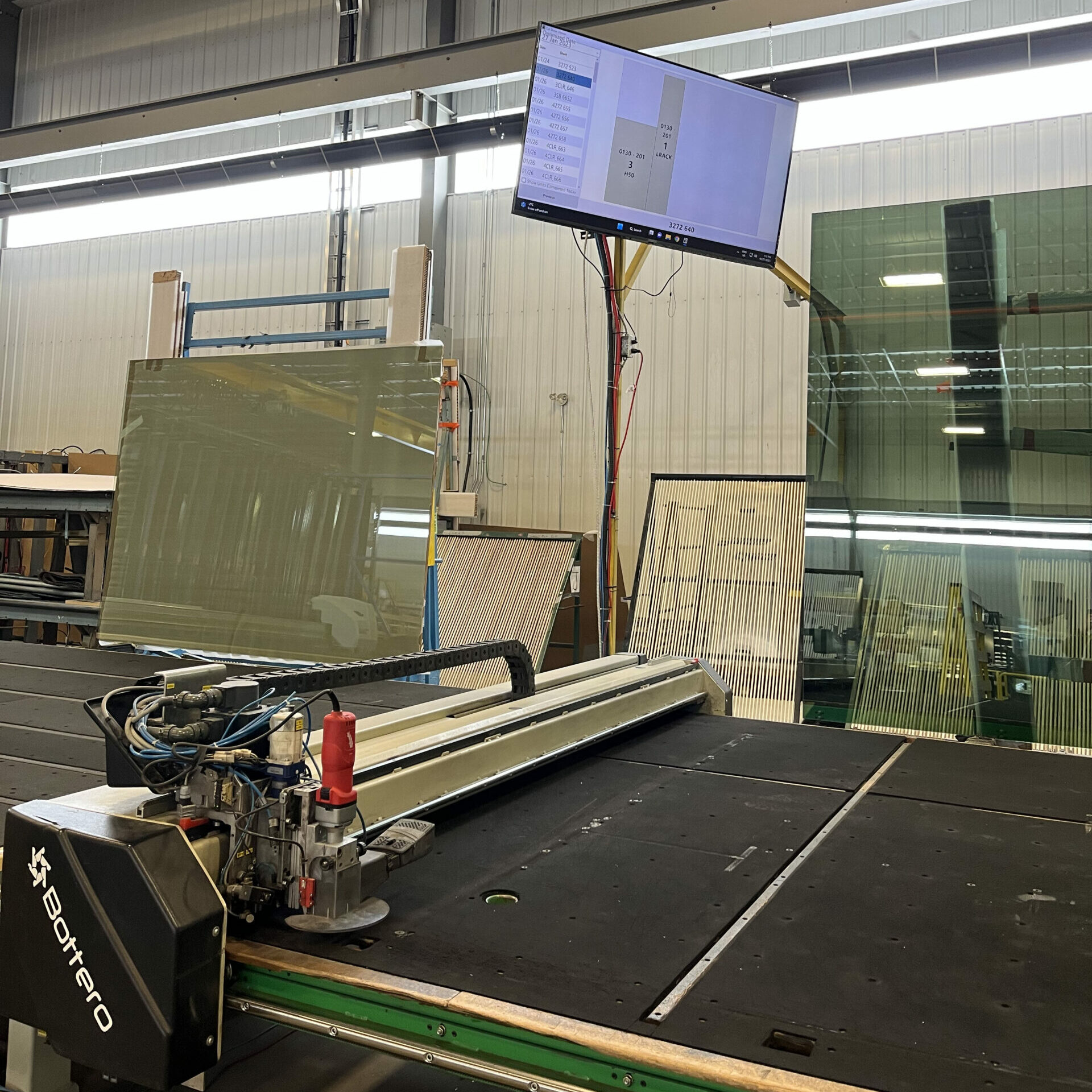

Glass Cutting

Automated glass cutting for IG production utilizes CNC (Computer Numerical Control) technology. The process involves programming the cutting machine with precise measurements and shapes required for each glass panel. The machine then uses a diamond-tipped cutting wheel or laser to score the glass along the programmed paths. After scoring, the glass is carefully separated along the scored lines, resulting in accurate and customized glass components ready for further processing and assembly into insulated glass units.

Glass Storage

Drawer systems for vertical glass storage are specialized storage solutions designed to safely and efficiently store large glass sheets in a vertical orientation. These systems consist of multiple drawers or compartments that can be pulled out individually for easy access to specific glass panels. The drawers are typically equipped with padded or cushioned surfaces to protect the glass from scratches or damage during storage and retrieval. Vertical glass storage systems with drawers help optimize space, enhance organization, and facilitate convenient handling of glass sheets, ensuring efficient inventory management in glass-related industries.

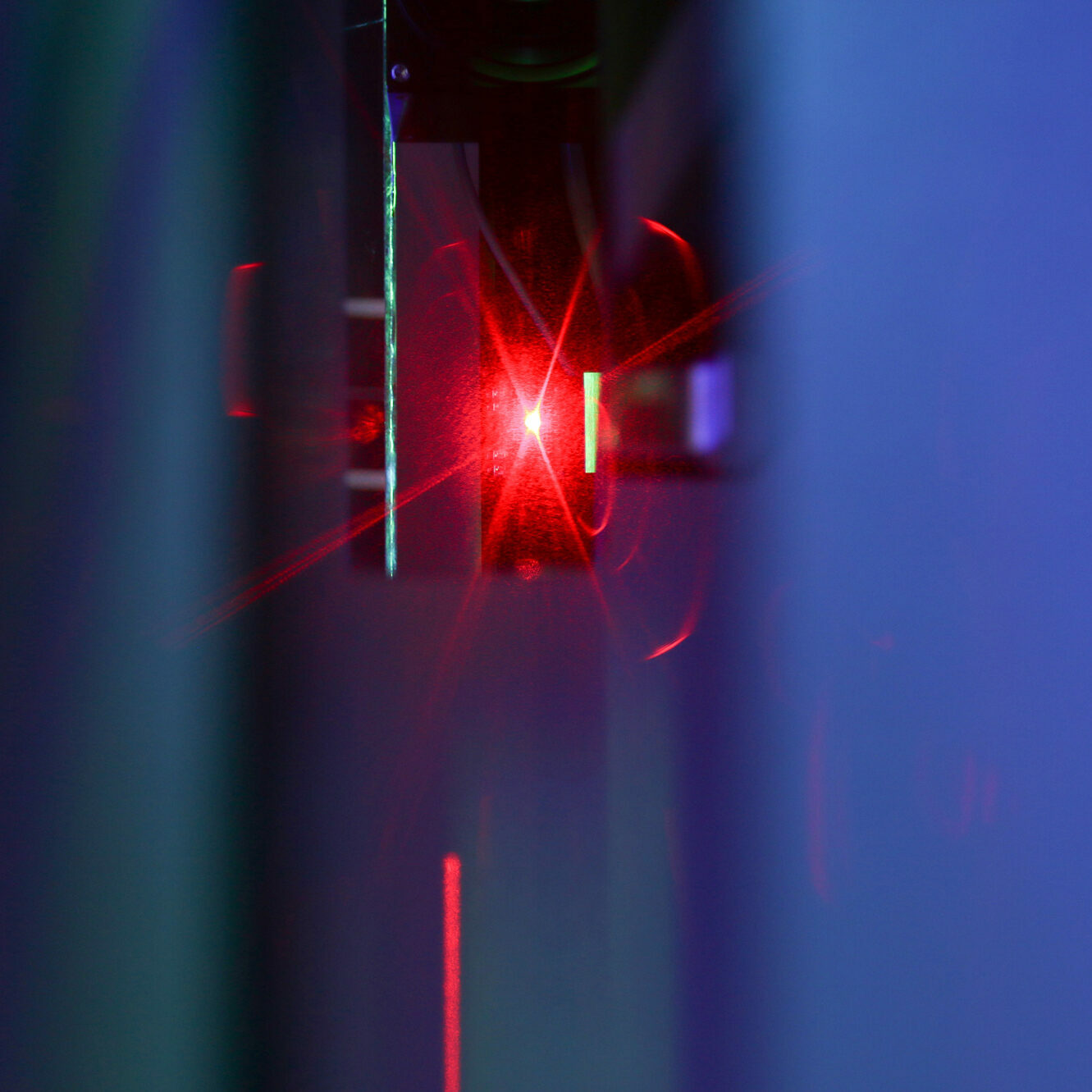

Quality Assurance

Optical glass defect detection machinery plays a crucial role in ensuring the quality and reliability of optical components. Utilizing advanced imaging systems, precision algorithms, and artificial intelligence, these machines can accurately identify and classify defects such as scratches, bubbles, or impurities. This automated inspection process enhances production efficiency, reduces waste, and guarantees the delivery of high-quality optical glass products to meet customer specifications.