As autumn settles in, temperature swings between crisp nights and warmer afternoons put windows to the test. These rapid changes often reveal weaknesses in insulated glass construction, especially along the edges where materials meet. This is where foam spacers prove their value. Unlike traditional metal spacers, foam spacers reduce heat transfer, limit condensation buildup, and extend the lifespan of sealed units, making them an essential feature for high-performance glass systems during the colder months.

How Foam Spacers Improve Window Performance

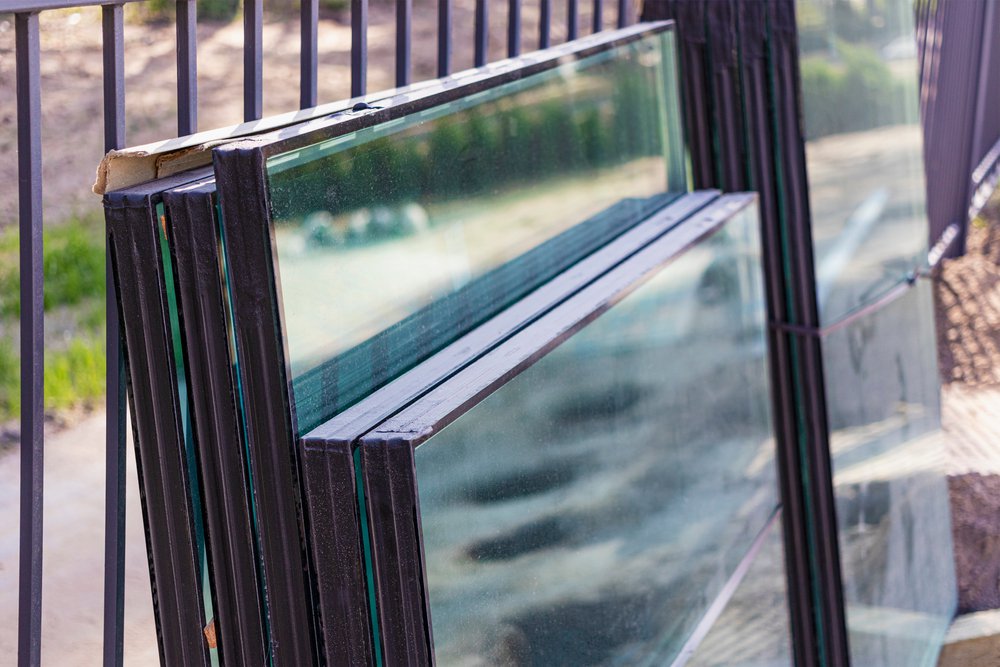

The spacer is the component that separates two panes of glass within a sealed unit. While it may look small, it has a major impact on the energy efficiency of the entire window. Foam spacers use flexible, insulating materials to create a thermal break at the glass edge. This design helps reduce heat loss, maintain consistent temperatures, and minimize the cold spots that often lead to condensation and discomfort.

Traditional aluminum spacers are highly conductive, which means they transfer cold into the sealed unit’s edge and allow heat to escape. Foam spacers act differently, keeping the edge warmer and reducing the likelihood of moisture forming when indoor humidity meets chilly glass surfaces.

Why Condensation Forms on Glass Edges

Condensation is one of the most common issues homeowners notice in fall and winter. It forms when warm, moist indoor air comes into contact with a cold surface, such as the edge of a windowpane. The cooler the edge temperature, the greater the risk of water droplets forming.

Foam spacers reduce this risk significantly by maintaining a warmer edge temperature. Instead of water pooling along the bottom of the window frame or streaking down the glass, the surface stays dry and clear. This improvement not only protects the window but also helps prevent damage to sills, frames, and surrounding finishes.

Foam Spacers and Seasonal Temperature Swings

Fall often brings dramatic temperature changes within a single day. Warm afternoons are quickly replaced by chilly evenings, and these fluctuations place stress on sealed units. Foam spacer bars are more flexible than rigid metal alternatives, which means they adapt better to thermal expansion and contraction.

This flexibility helps maintain the integrity of the seal between glass panes. With less stress placed on the sealant, the likelihood of premature unit failure is reduced. The result is a longer-lasting sealed unit that continues to perform consistently across seasons.

Energy Savings from Foam Spacers

Reducing condensation is just one advantage of this type of window spacer bars. The real long-term benefit is improved energy efficiency. By keeping the edge of the glass warmer, foam spacers prevent unnecessary heat loss, which means indoor temperatures stay more stable without overworking the heating system.

During fall and winter, this translates into noticeable savings on heating bills. Energy-efficient sealed units with foam spacer bars help maintain a more comfortable indoor environment while lowering operational costs for building owners. For contractors and builders, this provides a strong value proposition when offering high-performance window systems to clients.

Comfort and Clarity Indoors

Beyond efficiency, foam spacers contribute to overall indoor comfort. When glass edges remain warmer, the surface temperature of the window is more uniform. Occupants are less likely to experience cold drafts when standing near windows, and clear glass improves natural daylight and views.

This added comfort becomes especially valuable during the colder months, when people spend more time indoors. A window system that feels warm, clear, and reliable creates a better interior experience while enhancing the property’s appeal.

How Foam Spacers Support Longevity

The durability of sealed glass units depends heavily on how well components handle stress over time. Foam spacers provide a more stable edge environment by reducing thermal bridging and protecting sealants from repeated expansion and contraction. This stability helps extend the lifespan of sealed units, lowering long-term replacement and maintenance costs.

When combined with other advanced features such as Low-E coatings, sealed glass units with foam spacers provide a complete solution for energy efficiency and durability. The combination of technologies ensures that the window system performs optimally in all seasons, especially during the extreme demands of harsh winters.

Choosing High-Quality Sealed Glass Units with Foam Spacers

When selecting sealed units for projects, the spacer system should never be overlooked. Foam spacers deliver measurable improvements in performance, comfort, and longevity compared to older aluminum spacer technology. Whether used in residential or commercial applications, they support better outcomes for both installers and end users.

Working with a reliable manufacturer ensures access to sealed glass units that consistently meet performance standards. Custom solutions that incorporate foam spacers can be designed for a wide range of applications, from energy-efficient residential windows to high-performance commercial glazing systems.

Keep Yourself Warm This Coming Fall and Winter

Foam spacers are more than a detail in sealed glass unit construction. They play a direct role in reducing condensation, improving energy efficiency, and protecting windows from seasonal stress. As autumn brings shifting temperatures and winter approaches, having sealed units equipped with foam spacers makes a measurable difference in both comfort and performance.

At Insul-Lite Manufacturing™, we specialize in producing sealed glass units that are engineered for cold climates. Our units feature warm-edge foam spacers, Low-E coatings, and a variety of design options that deliver superior results for every project. With precision manufacturing and quick turnaround times, we provide reliable solutions that help prepare any property for the cold months ahead. Contact us today to learn more.